Ponyani zitsulo kabati zazitsulo, valani zinyalala ku ng'anjo yamagetsi

1. Njira yoponyera: Kuponyera nkhungu molunjika

2.Zitsulo kalasi: GX130CrSi29 (1.4777) (Komanso atha kukhala monga lamulo lanu)

3.Kulolera kwapadera kwa osewera: DIN EN ISO 8062-3 kalasi DCTG8

4. Kulekerera Kwazithunzi za cast: DIN EN ISO 8062 - GCTG 5

5. Phunziro pankhaniyi: Zinyalala zomera moto.

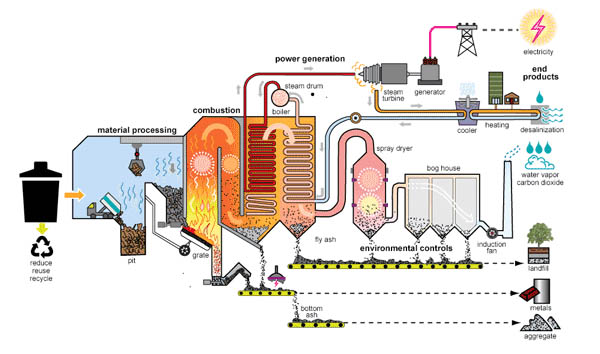

Kutaya zinyalala tsopano ndi vuto lalikulu padziko lonse lapansi. Zinyalala zamagetsi ndi njira yovomerezeka kwambiri pakadali pano. M'zaka zaposachedwa, mayiko ambiri omwe ali ndi mphamvu zachuma ayamba kulabadira izi. Ndalama zambiri zasungidwa pomanga malo opangira magetsi. Izi sizinangobweretsa kusintha kwakukulu ku chilengedwe chathu. Nthawi yomweyo, yatibweretsera zabwino zambiri zachuma.

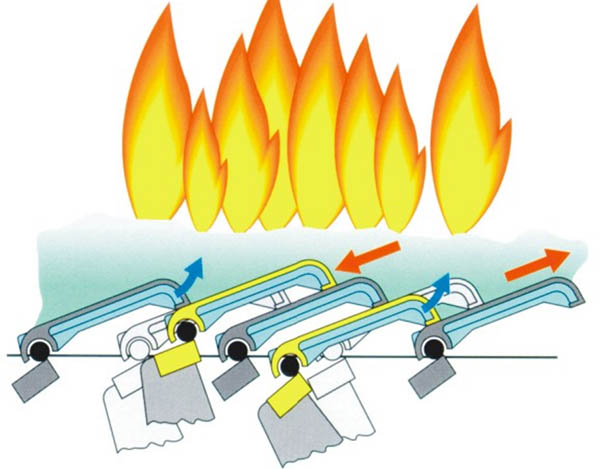

Monga momwe tawonetsera pachithunzichi, mipiringidzo yama kabati imathandiza kwambiri pakuwononga zinyalala. Kutentha kwambiri komanso malo ovuta kwambiri, kabati Yotsika kwambiri imakhudza kwambiri kuwotcha zinyalala, ndipo moyo wake wantchito ndi waufupi kwambiri. Muyenera kuzisintha pafupipafupi.

Komabe, ndi zaka zopitilira 10 ndikuponyera, titha kuthetsa mavuto anu.

Zitsulo kalasi timakonda ntchito. (Zitha kukhalanso monga zofunika zanu.)

Zida zamagetsi% zachitsulo GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Kupangidwa kwa mankhwala% achitsulo GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

Kupangidwa kwa mankhwala% achitsulo GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Kupangidwa kwa mankhwala% achitsulo GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mawotchi katundu (ASTM A297 kalasi HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Kutalika: mu 2 mu: Min 10% | |

| Kulimba: Min 200 BHN (malo atatu pachimake) " | |

| Microstructure / Chitsulo chosanja | Makamaka mawonekedwe aku Austenitic okhala ndi ma carbides omwazika |

| SoundnessTest / X-ray kapena UT | RT pa ASTM E446 Level II |

| UT pa ASTM A609 Level II | |

| NDT / LPI kapena MPI | MPI malinga ndi ASTM E709 / E125 LEVEL II |

| LPI malinga ndi ASTM E165 Level II " | |

| Kuyendera Komaliza | ASTM A802 Level II |

| Phukusi | Mlandu wa Iron kapena Mlandu wamatabwa. |

Msika Wathu Waukulu Ndi

OEMs ndi makampani amisiri

Zinyalala ku Zomera zamagetsi

Makampani ogwira ntchito

Zigawo zazomera

Zomera zamagetsi zamafuta

Makampani othandizira ntchito zokonzanso

Mitundu yosiyanasiyana ya mipiringidzo kabati OEM

Mabala a kabati omalizidwa bwino

Njira Zokhwima Ndikukhazikika Kwazinthu Zabwino Chifukwa Chiyani mutisankhira

Kuti mudziwe zambiri kapena mafunso okhudza luso, chonde lemberani XTJ Service Team. Tidzapereka yankho lanzeru kwambiri komanso mawu ogwidwa bwino kwambiri malinga ndi malonda anu.