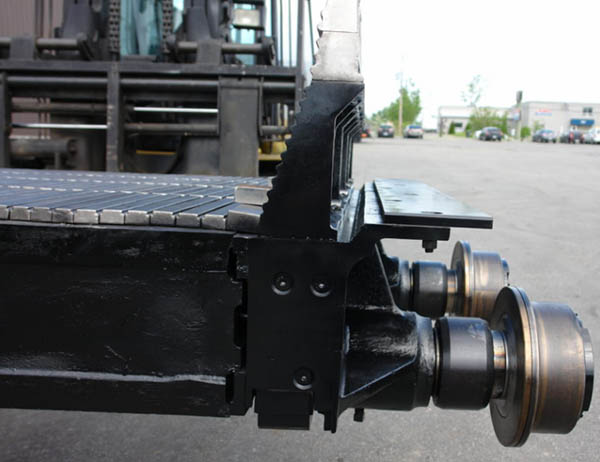

Kapamwamba kabati ndi khoma lakumbali, Valani Magawo pamagalimoto onyamula ndi magalimoto a sinter / pellet

1. Njira yoponyera: Kuponyera nkhungu molunjika

2. Zitsulo kalasi: 1.4777 1.4823 1.4837 1.4848

3.Kulolera kwapadera kwa osewera: DIN EN ISO 8062-3 kalasi DCTG8

4. Kulekerera Kwazithunzi za cast: DIN EN ISO 8062 - GCTG 5

5. Kugwiritsa Ntchito: Valani Magawo pamagalimoto amtanda ndi magalimoto a sinter.

Ndife otsogola otsogola kumagalimoto amphasa ndi opanga magalimoto a sinter komanso mphero zazikulu zachitsulo. Ndi zaka zoposa 10 'akuponyera, ziwalo zosagwira zomwe zimapangidwa ndi ife nthawi zonse zimakhala ndi makina abwino komanso abwino kwambiri. Tekinoloje yokhwima imayang'anira bwino momwe timapangira, kuti muthe kuyitanitsa zinthu zotsika mtengo kuchokera kwa ife. M'zaka zaposachedwa, kuchuluka kwa mphamvu zopangira kwatsimikiziranso tsiku lanu lobereka.

Zitsulo kalasi timakonda ntchito. Itha kukhalanso monga zofunika zanu.

Zida zamagetsi% zachitsulo GX130CrSi29 (1.4777): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

1.2 - 1.4 |

1 - 2.5 |

0.5 - 1 |

max 1 |

max 0.035 |

max 0.03 |

27 - 30 |

max 0.5 |

Kupangidwa kwa mankhwala% achitsulo GX40CrNiSi27-4 (1.4823): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 1.5 |

3 - 6 |

max 0.04 |

max 0.03 |

25 - 28 |

max 0.5 |

Kupangidwa kwa mankhwala% achitsulo GX40CrNiSi25-20 (1.4848): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

19 - 22 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

Kupangidwa kwa mankhwala% achitsulo GX40CrNiSi25-12 (1.4837): EN 10295-2002

|

C |

Si |

Mn |

Ndi |

P |

S |

Kr |

Mo |

|

0.3 - 0.5 |

1 - 2.5 |

max 2 |

11 - 14 |

max 0.04 |

max 0.03 |

24 - 27 |

max 0.5 |

| Mawotchi katundu (ASTM A297 kalasi HH) 1.4837 | UTS: Min 75 Ksi / 515 Mpa |

| YS: Min 35 Ksi / 240 Mpa | |

| Kutalika: mu 2 mu: Min 10% | |

| Kulimba: Min 200 BHN (malo atatu pachimake) " | |

| Microstructure / Chitsulo chosanja | Makamaka mawonekedwe aku Austenitic okhala ndi ma carbides omwazika |

| SoundnessTest / X-ray kapena UT | RT pa ASTM E446 Level II |

| UT pa ASTM A609 Level II | |

| NDT / LPI kapena MPI | MPI malinga ndi ASTM E709 / E125 LEVEL II |

| LPI malinga ndi ASTM E165 Level II " | |

| Kuyendera Komaliza | ASTM A802 Level II |

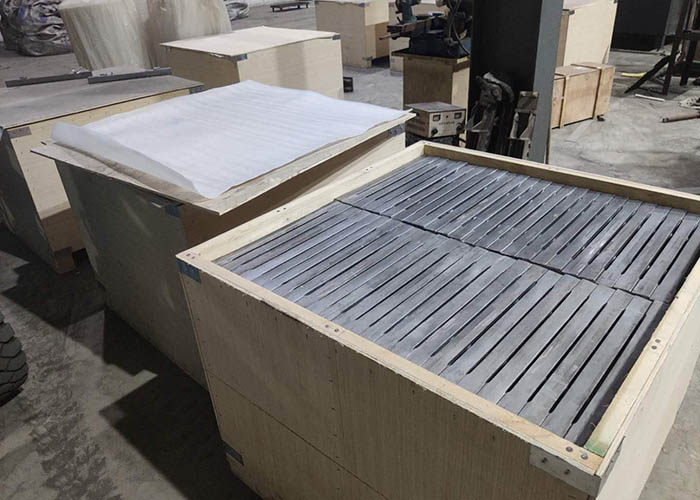

| Phukusi | Mlandu wa Iron kapena Mlandu wamatabwa. |

Mu chuma chamakono chamapikisano, kukhalabe ndi thanzi ndikuchepetsa ndalama kumatha kukhala kovuta kubizinesi iliyonse.

Koma mogwirizana ndi xtj, simuyenera kulingalira za izi. Ndife akatswiri fakitale, kotunga mwachindunji pambuyo kupanga. Ndipo pali akatswiri aluso komanso gulu logulitsa pambuyo kuti akupatseni ntchito zaukadaulo. Mwanjira iyi, mutha kupeza ntchito yabwino ndikuchepetsa mtengo.

Kuti mudziwe zambiri kapena mafunso okhudza luso, chonde lemberani XTJ Service Team. Tidzapereka yankho lanzeru kwambiri komanso mawu ogwidwa bwino kwambiri malinga ndi malonda anu.